Spray Foam Estimating Guide: Steps to Accurate Bids

How spray foam estimating works: Step-by-step guide to winning in a $900M market

When it comes to spray foam jobs, everything depends on the estimate. If you underestimate the job, you will lose profits, and if you overestimate it, you will lose potential clients. In both cases, your project’s fate basically depends on your cost calculations.

Even then, many contractors keep relying on guesswork, clunky spreadsheets, or outdated methods. This conventional approach results in missed material costs, inconsistent bids, and jobs that fail to deliver the margins they should have.

And with the U.S. spray foam insulation market projected to grow from $506.85 million in 2023 to over $900 million by 2032 (Credence Research, 2023), even minor mistakes in estimating could result in losing out on millions.

This blog is designed to clear up that confusion. In this, we’ll cover how:

- The spray foam cost estimating process actually works

- Why precision is important

- The most common mistakes you can avoid

- And how new estimating tools like Cleri.ai are helping contractors to create faster, more accurate estimates that win more work.

In spray foam projects, accuracy is more than just numbers on paper. It’s about customer trust, optimized profit, and repeat business.

Even a single bad estimate can create:

- Underbidding leads to profit loss, as material or labor costs eat into margins.

- Overbidding causes you to lose jobs to competitors who come in lower.

- Inconsistent bids damage credibility, leaving customers unsure about your expertise.

Clients want confidence and that’s only possible if you are consistent in your services. When your estimates are precise, it shows your professionalism. And when they’re sloppy, you lose credibility even before the first spray gun even comes out.

That’s why it’s super important to get the spray foam cost estimating process right from the start. It protects your profits and builds long-term customer trust.

3. Spray foam cost estimating basics

So, what makes a spray foam estimate reliable? The spray foam cost estimating process has multiple factors in various moving parts:

- Materials: The type of spray foam (open-cell vs closed-cell), coverage thickness, and total square footage drive most of the cost.

- Labor: The crew size, job complexity, and expected time on-site.

- Equipment: Like spray rigs, safety gear, and maintenance.

- Overhead: Such as insurance, transportation, waste disposal, and other indirect costs.

Every one of these factors matters. And even a minor miscalculation in square footage, or forgetting to account for setup time, can push your estimate far off track.

When estimating for a job, contractors often miscalculate in two places: failing to allow for waste and ignoring overhead. And slipping on any or both of these factors chips away at the profits they would have made easily, if these two factors were taken into consideration during initial estimation.

4. Common challenges faced in the spray foam cost estimating process

Even seasoned professionals run into challenges. Unlike other trades, the spray foam business has unique factors that make estimating pretty challenging.

- Material waste: Foam expands, and coverage isn’t always exact. A 5%–10% waste factor is common, but many forget to add it in.

- Labor variability: Two crews may complete the same job at different times, depending on experience and efficiency.

- Seasonal pricing: Material prices can fluctuate, especially during peak demand seasons.

- Math errors: Manual calculations or spreadsheet typos can undercut an entire project.

Spray foam jobs demand more careful estimation when compared to roofing or drywall, where material waste is more predictable and labor cycles are standard.

That’s why contractors who take the spray foam cost estimating process seriously usually see stronger margins and fewer surprises mid-job.

5. Step-by-step guide to the spray foam cost estimating process

Breaking the estimating process into clear steps makes it easier to repeat accurately every time. Here is the detailed breakdown of the estimating process into 6 steps:

6-Step process:

Step 1: Inspect site and take measurements

Take a walk around the space, check how easy it is to get in, spot any obstacles, and measure the square footage. Wrong measurements will result in wrong estimates.

Step 2: Calculate material needed

First, select the type of foam that you need for the job, open-cell or closed cell. Then you multiply the thickness of the foam by the square footage. This will tell you exactly the amount of material that you will need. It’s always a good practice to add a little extra for waste.

Step 3: Include labor hours

Create an estimate of the number of hours it will take to complete the job. Add in factors like the size of your crew and their job related experience. Large or hard to access areas usually take up more time.

Step 4: Include equipment and setup costs

Include rig use, generator fuel, protective equipment, and time spent preparing the site. It’s easy to overlook these costs but they can add up fast.

Step 5: Add overhead and profit margins

Calculate indirect expenses like insurance, admin, and transportation. Now add a profit margin to this calculation to ensure your business runs profitably.

Step 6: Deliver a professional quote

Package everything into a clear, client-friendly proposal. If you keep your estimates and client quotations transparent, it helps customers understand what they’re paying for, and it also strengthens their trust in your expertise.

If you apply this step-by-step spray foam cost estimating process consistently, it helps to reduce errors, protects your profit margins and helps you close your clients with more precision and confidence.

6. Real-world scenario

Let’s go through a simple attic insulation job estimate to see how the numbers add up.

Job Details:

- Square footage: 1,000 sq. ft.

- Foam type: Closed-cell, applied at 2 inches

- Material yield: 4,500 board feet per set

- Labor: 2-person crew, 1 full day

|

Step |

What’s Calculated |

Result |

|

1. Material calculation |

1,000 sq. ft. × 2 inches = 2,000 board feet. Add 10% waste factor. |

Budget for 1 full set of closed-cell foam. |

|

2. Labor |

2 workers × 8 hours + prep & cleanup. |

20 total labor hours. |

|

3. Equipment & overhead |

Rig use, fuel, PPE, insurance, transport. |

Added as indirect costs. |

|

4. Final estimate |

Add profit margin and package for the client. |

Clear, professional quote. |

In the entire estimation process, a small error or forgetting to add the waste factor can quickly make that job more painful than profitable.

For contractors, manually estimating the job can become slow and risky. That’s why many of them are shifting to spray foam estimating software like Cleri. Cleri helps automate the estimate, adds waste automatically, and produces an accurate quote in minutes.

7. Benefits of using technology for spray foam cost estimating process

Relying on spreadsheets or manual notes for estimating is time-consuming and errors happen all the time. A single misstep can create chaos and turn your profit into loss especially when you are handling multiple jobs at the same time.

With modern tools, the spray foam cost estimating process becomes faster and more reliable. You don’t have to manually estimate every job each time, the software automates the process for you. It adjusts for thickness, adds in waste, and gives you the right numbers fast.

Speed and accuracy are the real benefits of using estimating software.

It helps you:

- Deliver estimates faster.

- Gain customer’s trust.

- Close jobs efficiently even before your competitors have the chance to respond.

- Avoid the costly errors that come with manual estimating.

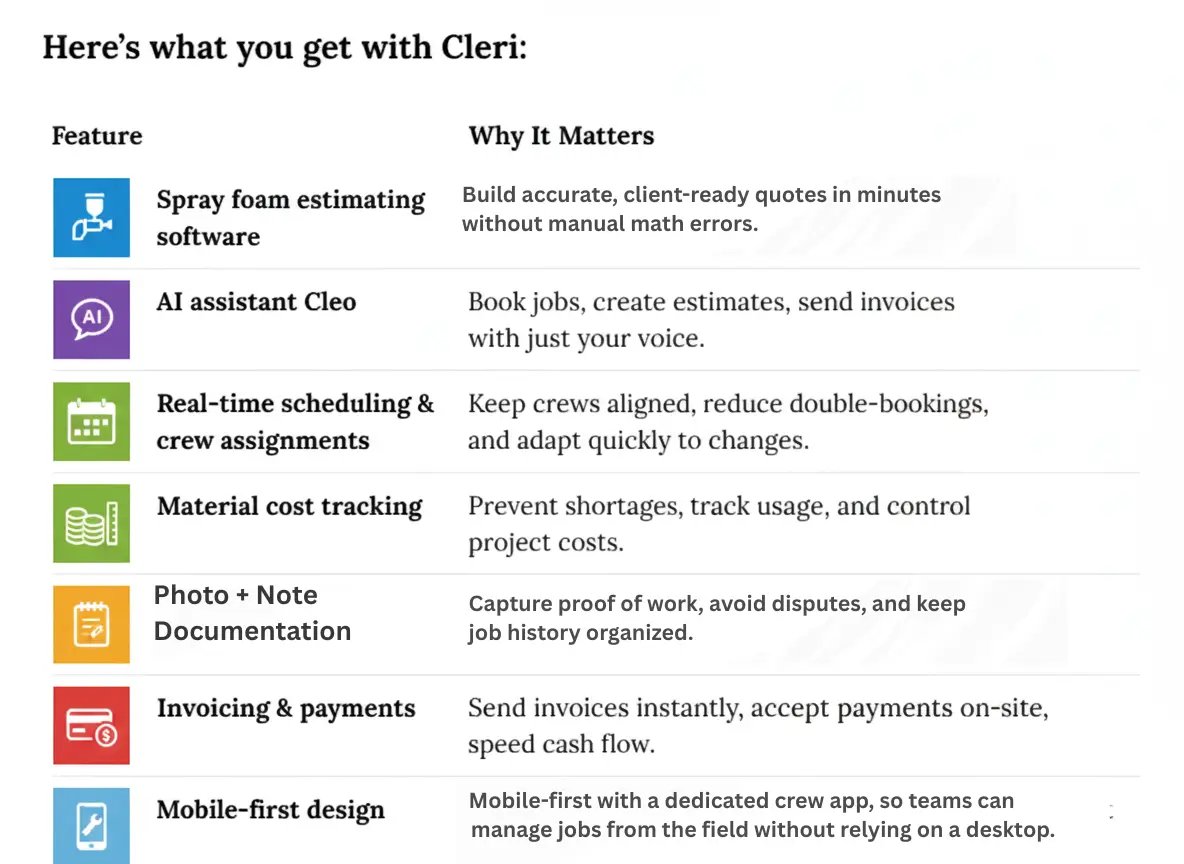

8. Why Cleri is built for spray foam estimating contractors

Spray foam jobs demand precision, and that’s exactly what Cleri delivers.

Unlike generic field service platforms, Cleri is designed around the day-to-day challenges of insulation and spray foam work, where one missed detail can throw off an entire project.

Cleri isn’t just another tool, it’s spray foam estimating software tailored to the way contractors actually work. It helps you send faster quotes, keep projects running smoothly, and protect your margins.

How Cleri makes this even easier

Cleri is built to simplify every step of this checklist. With Cleo, its voice-powered AI assistant, you can run estimates hands-free on-site without clicking through forms.

Unlike many platforms, Cleri includes all features in every plan, no paywalls, no locked tools. And if your crews are seasonal, you’ll love the flexible billing: you’re never charged for inactive users.

This way, Cleri not only keeps your estimates accurate, but it also makes running your spray foam business smoother and more cost-efficient.

9. How Cleri helps you avoid common estimating mistakes

Even experienced contractors fall into the same traps:

- Forgetting to add a waste factor.

- Underestimating labor hours.

- Losing time chasing data across files.

- Sending quotes that look unpolished.

Cleri is built to make the estimating process fast, accurate, and easy. It includes material wastage, keeps labor hours consistent, adds overhead automatically, and turns it all into a clean, professional quote.

This helps with fewer missed costs, better margins, and a quoting process you can trust to win more jobs without the usual errors.

10. Checklist for every spray foam estimate

To keep the spray foam cost estimating process consistent, every estimate should cover the same essentials.

|

Estimate Element |

Why It Matters |

|

Foam type |

Open-cell or closed-cell changes material yield and cost. |

|

Coverage thickness |

Impacts total board feet required. |

|

Total square footage |

Base calculation for materials and labor. |

|

Waste allowance |

Accounts for expansion and overspray (5–10%). |

|

Labor hours |

Varies by crew size and site complexity. |

|

Equipment use & setup |

Covers rig wear, fuel, and prep time. |

|

Overhead |

Insurance, transport, admin, disposal costs. |

|

Profit margin |

Ensures sustainable business growth. |

|

Client summary |

Builds trust with a clear, easy-to-read breakdown. |

With Cleri, these items are built into the estimating workflow, so nothing slips through the cracks.

11. Key points to remember

- If your estimating process is reliable and accurate, it builds customer trust in your services and increases your profit margins.

- The spray foam cost estimating process is full of unique challenges like waste, labor variability, and seasonal pricing. Without a reliable estimating tool, profit margins become uncertain.

- Manual methods lead to errors, delays, and missed revenue.

- Technology makes the process faster, more consistent, and more professional.

12. FAQs

Q 1: How long should it take to create a spray foam estimate?

With manual methods, it can take hours. But with the use of estimating software like Cleri, the estimating process can be accurately completed in minutes.

Q 2: What’s the biggest mistake contractors make when estimating spray foam jobs?

The biggest mistake spray foam contractors make when estimating jobs is overlooking material wastage and labor variability. And both these factors are crucial for correct profit calculations.

Q 3: How does software ensure accuracy?

Software ensures accuracy by automating calculations, accounting for wastage and using pre-set cost templates designed for spray foam estimations.

Q 4: Can I use Cleri for more than spray foam?

Yes. Cleri is built for multiple trades. But when you use its spray foam estimating software, it adapts specifically to spray foam estimating with pre-loaded templates and workflows that match your jobs.

Ready to transform your spray foam estimating business?

Running a spray foam business is already challenging. But it can be made easier and more accurate with the right tools for the spray foam cost estimating process.

Smart tools like Cleri help run your spray foam business with great accuracy and ease. It fully automates your estimating process and uses features that are specifically designed to reduce errors and increase your profit margins.

If you are seriously looking for an upgrade for your spray foam estimating process, try Cleri’s free trial and see the difference in real time.

Try Cleri free for 14 days.

No credit card. No setup calls. Just your real jobs, your real crew, and a smoother, more profitable week.

Related Articles

Lawn Care Estimating: How Modern Software Makes Quoting Faster and More Accurate

Lawn care estimating & quoting software: The tool...

Lawn Care Accounting Software for Smarter Job Costs & Faster Billing

Streamline your business with lawn care...

ROI of Window Cleaning Software: Real Gains for Pros

The ROI of Window Cleaning Software: Is It Worth...

.webp)

Top Spray Foam Estimating Software Features for 2026

Features to look for in spray foam estimating...

Insights and Tips for Small Business Success

Starting and running a small business can be both...

Franchise management made easy for lawn care businesses.

How to boost profits and cut admin by 50%

...

Benefits for contractors: Why spray foam estimating software is a game-changer in 2026

Running a foam insulation business successfully...

Cloud-Based Software for Field Services | $12.85B Market Shift

Introduction: The ultimate shift in field services

Lawn Care Scheduling Software: Grow Faster With Smarter Tools

Lawn care scheduling software: How your business...

How software can help scale your window cleaning operations: See how businesses using software complete 47% more jobs daily

Running a window cleaning business is more than...

Top Features in Blue Collar Automation Tools

Blue-collar businesses in today's time need more...

10 Tech Advantages for Window Cleaning Success

10 proven advantages of using technology to...

.png)

Try Cleri’s 14-day free trial and

see for yourself

No credit card. No setup calls. Just your real jobs, your real crew, and a

smoother, more predictable week.